INTELLIGENT SENSORS AND ANALYTICS POWERING THE NEXT WAVE OF GRID DIGITALIZATION

- Sentient Energy

Almost every sector of the modern economy is going through a digital transformation by leveraging ubiquitous connectivity, elastic computing, edge and cloud applications enabled in part by new data streams from the edge devices that were not previously available. Collectively bundled under various industry terms, the Industrial Internet of Things (IIoT) is shaping up to be the next major catalyzer for business transformation at least an order of magnitude better than the Internet did in the 90s and 2000s. So how exactly is this taking place at the utilities sector and more specifically for electric energy distribution and delivery?

It is perhaps a gross underestimation to think of the utility industry as being new to digitalization and innovation. Since the inception of on-board computing and telecommunications, electric utilities have relied on various digital technologies in the field and in the control center to achieve the business objective of delivering safe, reliable, and affordable power to residential, commercial, and industrial customers. While those traditional objectives remained the same over the century old history of electric power production and delivery, a number of market and societal forces are adding new terms to the industry’s mission statement, some are characterized by terms like “clean”, “sustainable”, and “consumer and environment-friendly”. What that means varies from region to region and from state to state but the commonality is that there is no business-as-usual anymore and this is where a new wave of digitalization hits the bottom line of corporate objectives. Distributed Energy Resources (DERs) such as solar PV, wind, storage, EVs, demand response, and microgrids are increasingly finding their fair share of the generation and storage mix and with that comes the need for better situational awareness and grid management tools and technologies.

The dominant unidirectional flow of power and deterministic supply and demand in the past made it possible to measure, monitor, and control the grid primarily at the extremities i.e. substations via Intelligent Electronics Devices (IEDs) and at delivery points via occasional data pulls from meters and controls from discrete points along the feeder back-bone. This is no longer the case when electric utilities need to embrace DER technologies and integrate them into their planning and operations through a DER management solution (DERMS). With the decades-old engineering assumptions and models being challenged everyday by the new forms of generation and consumption, electric utilities are increasingly finding it compelling to invest in the new wave of digitalization and move towards creating an enabling platform for plug-and-play energy production and consumption. While that may be years away from being the new norm and business model and won’t happen overnight, the steppingstone to move up in the digital journey include new ways to optimize operation and maintenance costs and do more with less everyday.

Commonly referred to as the “digital S-curve”, it represents the different milestones in achieving the full spectrum of digitalization benefits and if we look at the state of digitalization across the board, it’s not a uniform distribution. Rather, we see the bulk of the market getting started with covering the gaps or augmenting the current coverage for measurement and control between the network extremities by instrumenting branches, laterals, and low-voltage networks and connecting them to the cloud. To that end, intelligent line sensors and other IoT devices are increasingly used in transmission and distribution systems to enhance system observability and controllability along the line of the old adage “you cannot control what you cannot measure”. Compared to their traditional counterparts with local annunciation and single-purpose design, these multi-functional IoT devices feature advanced capabilities that not only cover the traditional reliability use cases such as SAIDI and SAIFI improvements but more importantly they help set the stage for the next wave of digitalization with high fidelity GPS precision time synchronization across the entire coverage area. Together with the operational technologies in the control room, this level of time and space precision in new digital data present an unprecedented opportunities for grid modernization and management of DERs, shedding light to system dynamics and emerging conditions that have not been observed at this scale in the past. True to their promise, these sensors are equipped with on-board compute, storage, and communications making them an ideal fit for utility IoT applications at the edge of the grid. The sensors distributed across the system benefit from GPS precision timestamping and synchronization in microseconds. Featuring relatively high sampling frequencies, these IoT devices produce high fidelity signals that provide new ways to measure and characterize system behavior during steady-state and transient conditions. Measurements from multiple sensors can further be aggregated in a centralized computer system or a field gateway powering system level applications such as outage and asset management.

With the aforementioned, it is probably clear to think of intelligent sensors and advanced analytics as key enablers for business transformation and digitalization. This is however the first important step. More data without an end-to-end domain-based analytics and integration is only going to exacerbate the data deluge situation that many early adopters consider as a significant hurdle in realizing the full value of IoT investments. Coupled with enterprise level analytics and integration, the data become a new digital asset fueling the insights and actionable knowledge that ultimately contribute to better business outcomes. The Intelligent Sensing, Control, and Analysis Network or ISCAN concept encapsulates all of the prerequisites to make this happen.

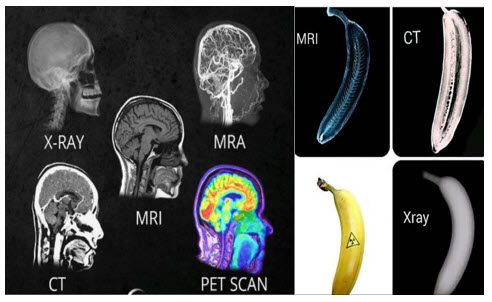

Intelligent sensors produce new raw data streams that augment existing data in the protection and automation systems. In some cases, they produce a new level of visibility into dynamics and disturbances that were previously unobservable. For example, pre-fault signatures can now be observed and characterized across the whole system for proactive fault notification and management. The difference for decision making is analogous to advanced techniques used in medical imaging. While X-rays are effective in diagnosing bone fractures, decay, and other developed conditions, detecting the early signs of a disease at the cellular level is only possible with a PET Scan. Similarly, intelligent sensors can be configured to pick up and report the early signs of a developing issue weeks, days, or hours in advance before it leads to an outage. In other cases, this level of intelligence provides the necessary details into the actual circumstances of a confirmed fault in real-time helping to prioritize and optimize restoration and crew response.

Intelligent sensors produce new raw data streams that augment existing data in the protection and automation systems. In some cases, they produce a new level of visibility into dynamics and disturbances that were previously unobservable. For example, pre-fault signatures can now be observed and characterized across the whole system for proactive fault notification and management. The difference for decision making is analogous to advanced techniques used in medical imaging. While X-rays are effective in diagnosing bone fractures, decay, and other developed conditions, detecting the early signs of a disease at the cellular level is only possible with a PET Scan. Similarly, intelligent sensors can be configured to pick up and report the early signs of a developing issue weeks, days, or hours in advance before it leads to an outage. In other cases, this level of intelligence provides the necessary details into the actual circumstances of a confirmed fault in real-time helping to prioritize and optimize restoration and crew response.

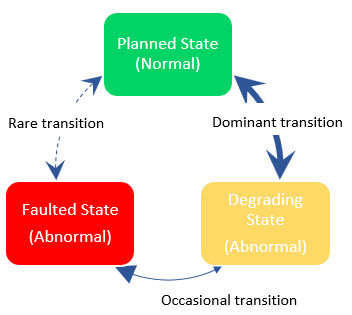

In summary, the new wave of digitalization is advancing the current grayscale view of system states (normal/faulted) to a more colorful view with a minimum of three dominant states (normal, degrading, and faulted). Intelligent sensors and analytics of this decade are helping to define the third dominant state better and in a more granular way above and beyond what SCADA did in the 60s, DMS in the 80s and 90s, and AMI in the mid-2000s. And, the promise of the next decade for continued digitalization and decarbonization is to integrate all of the digital technologies end-to-end including DERMS and ISCAN to empower network planners, operators, and asset managers to understand and respond to developing grid issues in the degrading state and minimize the downtime and outages in the faulted state towards a safer, more reliable, affordable, and sustainable electric delivery system.

In summary, the new wave of digitalization is advancing the current grayscale view of system states (normal/faulted) to a more colorful view with a minimum of three dominant states (normal, degrading, and faulted). Intelligent sensors and analytics of this decade are helping to define the third dominant state better and in a more granular way above and beyond what SCADA did in the 60s, DMS in the 80s and 90s, and AMI in the mid-2000s. And, the promise of the next decade for continued digitalization and decarbonization is to integrate all of the digital technologies end-to-end including DERMS and ISCAN to empower network planners, operators, and asset managers to understand and respond to developing grid issues in the degrading state and minimize the downtime and outages in the faulted state towards a safer, more reliable, affordable, and sustainable electric delivery system.