Fault Detection & Location

Why Fault Detection is Important

Sentient Energy’s intelligent sensors use advanced fault detection algorithms to sense system faults in real-time. They wirelessly communicate fault information immediately to the utility control center for integration with SCADA, DMS, or OMS systems.

With more precise fault location information, operators can dispatch crews to the correct location, reducing patrol time and outage duration. The sensors display an LED so field crews can verify fault detection when they arrive.

How Intelligent Line Sensors Work

Intelligent sensors MM3™, ZM1™, UM3+™, and UM1™ using the cFCI application, are installed on overhead and underground lines at primary switching points, between switch locations, on significantly loaded laterals, or on long laterals where patrolling is time consuming. Sentient Energy’s Ample® Analytics Platform serves not only as the data repository and analytics platform but as the integration platform for SCADA and DMS.

Key Features of Overhead and Underground Line Sensors

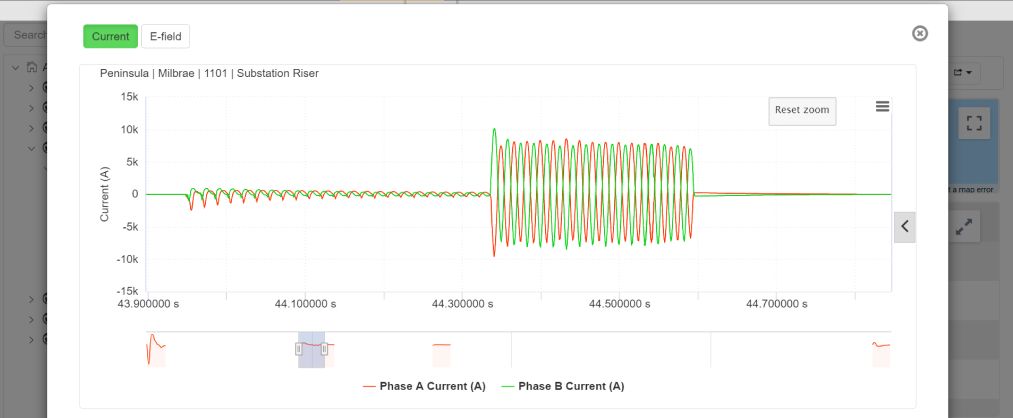

Sentient Energy overhead and underground sensors capture numerous elements of distribution system status to detect and better understand faults and interruptions.

- Fault current measurement

- Fault magnitude measurement

- Multiple fault detection algorithms and in-rush restraint options

- Identification of faulted phase or phases

- Fault waveform (oscillography) capture

- Loss-of-source detection

- Impervious to adjacent fields and high-frequency false tripping

- IEEE 495-2007 compliant

- NIST traceable fault and load measurements

- Immediate confirmation of service restoration

Fault Detection & Location Benefits

- Sentient Energy’s intelligent sensors with Ample Analytics are a proven way to shorten outage durations for permanent faults and improve SAIDI metrics.

- Utilities improve reliability and their customers are more satisfied.

- In addition to fault detection, Sentient Energy Intelligent Sensors are capable of interval load logging (Log-I) and high-resolution oscillography capture (Waveform).